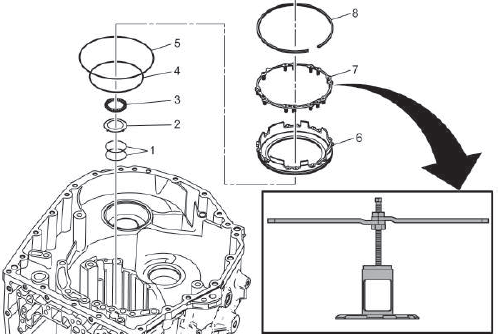

Buick Regal: Low and Reverse Clutch Piston Installation

- Direct Clutch Fluid Seal Ring [2x]

- Direct Clutch Hub Thrust Bearing Race

- 2nd Clutch Housing Rear Bearing

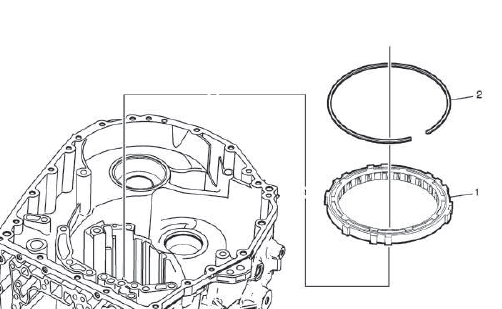

- Low and Reverse Clutch Application Ring

- Low and Reverse Clutch Application Ring

- Low and Reverse Clutch Piston

- 1-Reverse Clutch Spring

- 1-Reverse Clutch Spring Retaining Ring

Procedure

Using the DT-48056 bridge with DT-48903 and DT-51920 compressors, install the retaining ring.

NOTE: Ensure DT-51920 Clutch Spring Compressor is clocked properly and only making contact with the 1-Reverse clutch spring.

Special Tools

- DT-48056 Spring Compressor Bridge

- DT-48903 Spring Compressor

- DT-51920 Clutch Spring Compressor

Equivalent regional tools: Refer to Special Tools

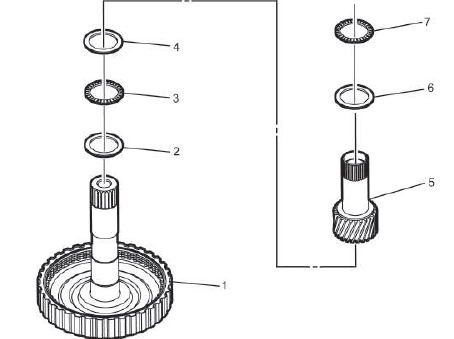

DIRECT CLUTCH ASSEMBLY INSTALLATION

- Direct Clutch

- Direct Clutch Hub Thrust Bearing Race

- Direct Clutch Bearing

- Rear Sun Gear Thrust Bearing Race

- Rear Sun Gear

- Rear Sun Gear Thrust Bearing Race

- Rear Sun Gear Thrust Bearing

REAR CARRIER INSTALLATION

- Rear Carrier Thrust Washer

- Rear Carrier

Procedure

- Assemble this on the table with Direct Clutch Assembly Installation.

- Rotate till seated completely.

- Install complete direct clutch and rear carrier assembly as a unit.

- Rear Carrier Thrust Washer

- Sun Gear

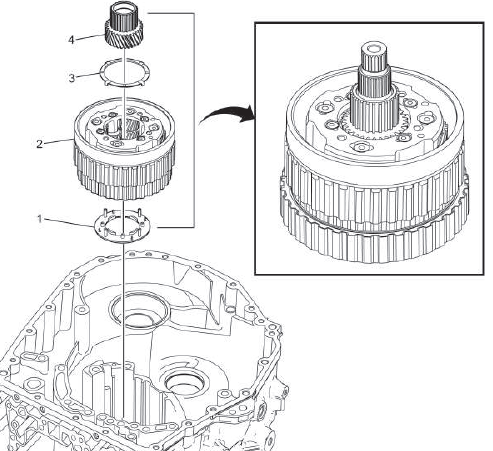

1ST AND REVERSE CLUTCH BACKING PLATE INSTALLATION

- 1st and Reverse Clutch Backing Plate

NOTE: Machined side down.

- 1st and Reverse Clutch Plate

- 1st and Reverse Clutch Plate - Friction Plate

- Forward Clutch Backing Plate

NOTE: Groove up to accept the retaining ring.

- 1-Reverse Clutch Backing Plate Retaining Ring

OVERRUN CLUTCH INSTALLATION

- Overrun Clutch

NOTE: Rotate the rear carrier clockwise while installing.

- Overrun Clutch Retaining Ring

NOTE: Rotate the rear carrier clockwise until fully seated to accept retaining ring.

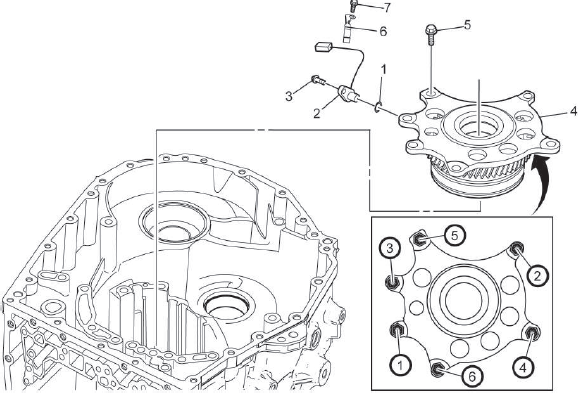

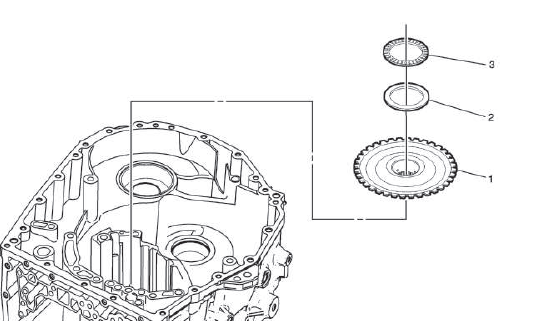

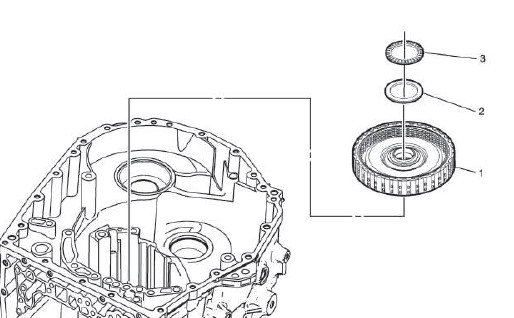

COUNTER DRIVE GEAR INSTALLATION

Fig. 3: Automatic Transmission Counter Drive Gear Bolts Tightening Sequence

- Vehicle Speed Sensor Spacer

- Vehicle Speed Sensor

- Automatic Transmission Intermediate Speed Sensor Bolt

CAUTION: Refer to Fastener Caution.

Tighten 5 N.m (44 lb in)

- Counter Drive Gear

- Center Support Bolt[6x]

Tighten in sequence 62 N.m (46 lb ft)

- Automatic Transmission Control Wiring Harness Clamp

- Front Differential Transfer Drive Gear Fluid Passage Tube Bolt

Tighten 7 N.m (62 lb in)

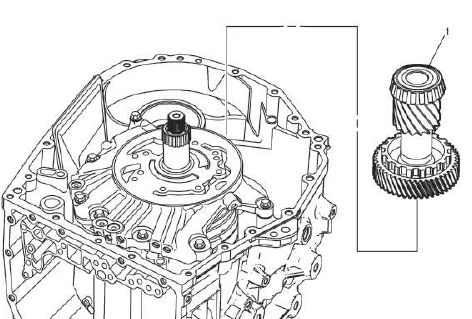

FINAL DRIVE PINION AND RING GEAR INSTALLATION

- Final Drive Pinion and Ring Gear

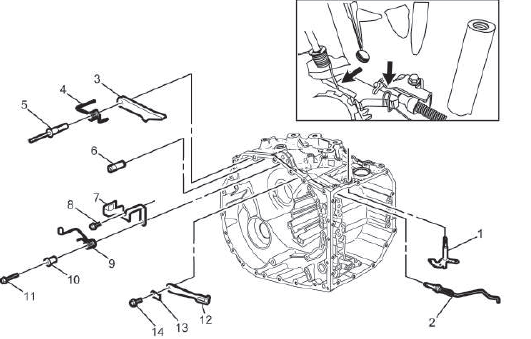

MANUAL SHIFT DETENT LEVER AND PARK PAWL INSTALLATION

Lubricant Fluid Pipe Installation

- Automatic Transmission Vent Baffle Cover

- Torque Converter and Differential Housing Bolt

CAUTION: Refer to Fastener Caution.

Tighten 7 N.m (62 lb in)

- Automatic Transmission Vent Baffle Cover

- Torque Converter and Differential Housing Bolt

Tighten 7 N.m (62 lb in)

- Lubricant Fluid Pipe

- Lubricant Fluid Pipe Retainer

- Automatic Transmission Control Wiring Harness Clamp

- Front Differential Transfer Drive Gear Fluid Passage Tube Bolt [2x]

Tighten 7 N.m (62 lb in)

Park Components Installation

- Manual Shift Shaft Lever

- Park Pawl Actuator Rod

NOTE: Rotate the manual shift shaft lever to get rod in place.

- Park Pawl

- Park Pawl Spring

NOTE: Ensure spring is in proper location like the inset shows.

- Park Pawl Shaft

- Park Pawl Lockout Pin

- Park Pawl Actuator Bracket

NOTE: Ensure park pawl actuator rod is in proper location like the inset shows before tightening the bolts.

- Park Pawl Actuator Bracket Bolt

CAUTION: Refer to Fastener Caution.

Tighten 9 N.m (80 lb in)

- Park Pawl Pin Spring Guide Sleeve

- Park Pawl Actuator Lever Spring

NOTE: Ensure Spring is in proper location like the inset shows.

- Park Pawl Actuator Bracket Bolt

Tighten 9 N.m (80 lb in)

- Manual Shift Detent Lever Spring

- Automatic Transmission Control Lever Detent Spring

- Manual Shift Detent Bolt

Tighten 10 N.m (89 lb in)

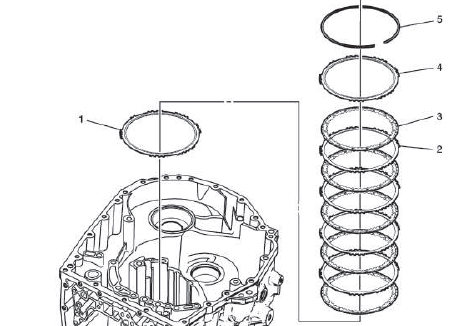

INPUT DRUM INSTALLATION

- Input Drum

- Sun Gear Front Thrust Bearing Race

- Input Sun Gear Thrust Bearing

FORWARD CLUTCH ASSEMBLY INSTALLATION

- Forward Clutch

- Forward Clutch Housing Thrust Bearing Race

- Input Clutch Housing Thrust Bearing